Audi, Volkswagen Seat, and Skoda

The infamous balance shaft sprocket of the 2.0 TFSI – The issue and what to do about it!

In this post we will cover all there is to know about, like the headline says: The infamous balance shaft sprocket of the 2.0 TFSI – The issue and what to do about it! So without further due, lets get started.

What is the balance shaft sprocket?

The 2.0 TFSI engine is installed in a lot of vehicles produced by the manufacturers Volkswagen, Audi, Skoda and Seat. KTM X-bow uses it as well.

Throughout the years there have beens some variations and even a completely new base engine has been introduced. The once we are focusing on in this article, are all built upon the EA113 platform, you can check your engine code for reference.

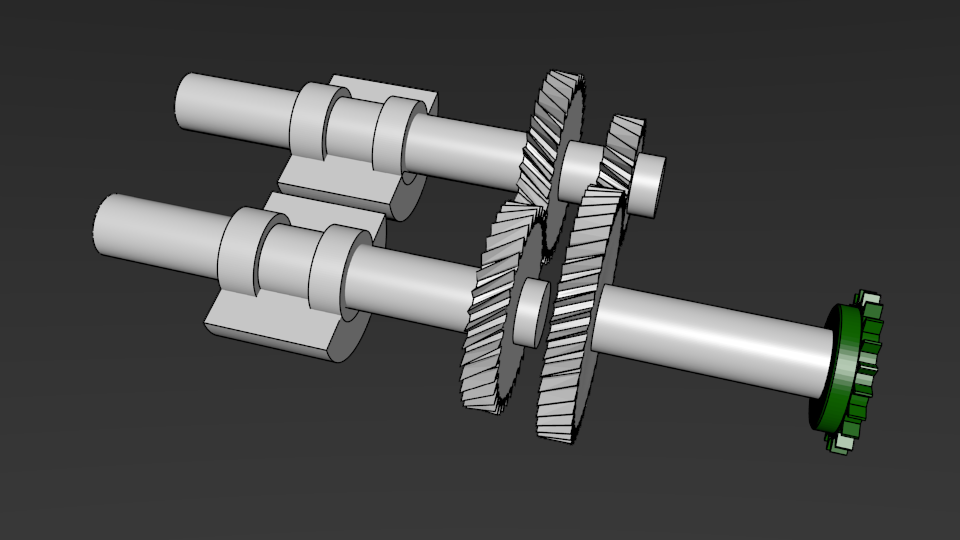

These engines use a special kind of combined balance shaft and oil pump unit, or module if you will.

In this module two balance shafts can be found, counter rotating to each other with double engine RPM.

The oil pump and one of those balance shafts have one chain sprocket attached them each and it is the one the shaft that is giving people issues. It is really the weakest link in the entire motor.

TFSI 2.0 Balance shaft assembly

The engine RPM is transfered inside the module with a gear ratio of 1:2

let us take a closer look at the sprocket

In order to better understand what actually happens when the sprocket fails, we first need to be aware of an issue and constant challenge for the engineers tasked with developing new engines.

Because of the emission regulations forced upon the industry, engines are pushed further to their limits. They have to deliver high power output from a small cylinder displacement and weight. We see flywheels turn into dual mass and even lightweight bolts. Everything is being optimized.

This does not come without its new problems.

If we look at this particular engine, we can see the problem has for instance shown itself in fluctuations throughout the rotating parts. The rotation av a crankshaft is never constant but rather consists of accelerations and decelerations.

The fluctuations caused by this are transered to all components driven directly by the crankshaft. Because the balancer shafts are relatively heavy, VAG fitted a chain sprocket with an internal damping system to protect the chain form breaking. However this merely moved the problem down the line.

The issue within

With the chain releaved from stress, the force has been moved to the damper inside the sprocket. This works rather well. For a while. Just like any springs would, even those in the sprocket do get exhausted over time.

When they do to a certain point the result will be the sprocket starting to hit its limits, which has an similar effect as the on found in an impact wrench. Eventually the sprocket will brake with torn chain and no oil pressure to show for it.

So what is there to do about this now?

If the engineers from VAG would have thought this whole chain of events through, they could have solved the issue at hand in a very different matter. For instance they could have designed a system for the sprocked to be hydraulically dampened in order to absorb the energy.

But since this was not the case, we have got what we got today to work with. We manufacture and sell to different solutions to this problem. The first one is a solid sprocket and the second is a kit to disable the balancer shafts all together. I personally always recommend the latter one.

Balance shaft delete

By completely disabling the balance shafts, the stress left on the chain is almost not worth mentioning.

The modification also makes the engine a bit more responsive to the throttle because there is less weight to be accelerated.

Also there is no risk of other common issues regarding the shafts, such as as seizing or excessive play.

We have invented our own solution, which we call “the freewheel” to make it as easy as possible for TFSI owners to install. No cutting or drilling needed. Simply remove one bolt and replace. The kit has been engineered and manufactured by ourselves in sweden, guaranteeing the highest standard of quality and performance. Eventually someone will try and copy it, but this will always be the original.

The simple yet ingenious part of our solution makes it possible to undo if desired.

With over 500 kits sold to date (2019-10-27), in sweden alone, there has been only one complaint regarding vibrations. In that case the engine had 520hp and extra hard mounts installed. The customer choose to install our solid sprocket instead.

solid sprocked

The other soultion we offer is a sprocket made as one solid part, without the troublesome damping. I myself would go with the delete option, since this one does not come with the ame advantages. The freewheel is the most reliable solution by far.

That being said, a lot of customers still go with this solid sprocket. It is really a matter of opinion, since the price is the same for both.

Other solutions out there

A quick google shows there are many different fixes to be found, some of them we have encountered in our workshop. Because of having examined those, we feel very confident that our concept is the most thought through out there.

Let us have a look at some of them.

Poor mans delete

Before we started selling the freewheel solution, the so called “Poor mans delete” was the most common one to see. This is done by cutting the sprockets inside the module so the shafts are no longer driven.

The downside is of course that you are ruining your module and you cannot undo this to regain the funtcion of the balancer shafts.

Also one of the more prone to fail sliding bearings will still be in use.

New sprocket of “OEM design”

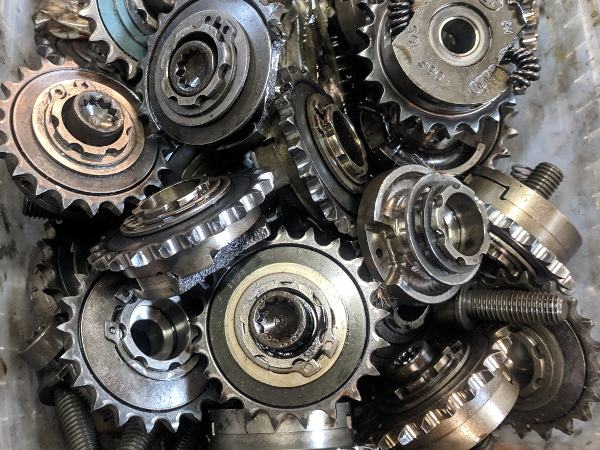

The sprocket we are talking about here has never been available from VW / Audi, and probably never will be. Yet there some to be found on the world wide web, which look almost identical to the original. All of them are copies from China.

We have been working on a couple of cars where they have been previously installed, and have therefore been given a good chance of studying theme a bit closer.

Apart from our doubts that their springs could withstand what the OEM could not, we have found something interesting. Most of them seem to be missing one very important component. On the OEM there is a small diamond washer making sure the sprocket is fixed into place without slipping. This washer seems to be missing on the ones we have encountered. In a bad scenario a slipping sprocket could lead to damaging the shaft end.

Also we have seen product images on the internet where you can see clearly that the sprocket is not centered even before being installed. This is because the internal springs are of different stiffness.

Just the other week I received an e-mail from a customer who bought our freewheel. He wrote to tell us about his experience with the chinese sprocket. According to him the car went well for about 50km before starting vibrate again due to the springs failing.

Chinese and OEM compared

To the left you can see the chinese sprocket without the washer and the right one is an OEM sprocket that has been replaced as a precaution. The chinese has spun and damaged the shaft.

Solid design sprockets from our competitors

On Ebay there quite a few solid design sprockets to choose from. Some of these we have encountered in our shop as well, when customers bring their car in with low oil pressure or vibration isssues.

The most common mistake we have seen, is the engineers trying to replicate the visual design of the sprocket.This adds unecessary weight to it and resulting in increased moment of inertia. Our sprocket is designed, keeping this in mind, to be as light weight as possible without sacrificing its durability.

The second design flaw we see a lot is, just like the chinese copies, the lack of using a washer up to the task. We use a special kind of washer which we have developed and tested for this application only.

OEM and Aftermarket sprocket

This sprocket is designed to resemble the OEM, which means it is unnecessery heavy and it also lacks the diamond washer. Because of this it has been spinning on the shaft, damaging it.

I have 2008 Audi A4 TFSI engine with 85,000 miles on it. The whole engine has been built for bigger turbo application. After installing the WASA balancer shaft delete I notice my low oil pressure light come randomly ar low idle. Oil pump is new . Oil is pressure is good too. Is this common after installing the Wasa finds her shop delete? Any info would help! Thanks

Hi Andres,

as long as you can confirm there is oil pressure, the issue can’t be traced to the freewheel. It sounds more like an issue related to bearings or piston squirters. Maybe even electrical.

P.S. Could also be debris in the regulating system. Especially if there has been an earlier sprocket failure or a cam follower was replaced too late.

Best Regards

Hannes Finnilä

How do you hold the balance shaft to remove the original bolt?

Hi Tim,

you can insert a pin through one of the drainage holes, to stop the shafts from rotating.

/Hannes

Will this fit on a 2009 Audi A4 2.0 T Quattro cabriolet engine code is BWT

Hi David,

Yes, it should.

/Hannes

Kada se ugradi Wasa Freewheel, dali bi trebalo blokirati balansnu osovinu ili je pustit u slobodan hod. Ja sam ugradio Wasa FreeWheel i na 5.500rmp se osjete vibracije.

Hi Darko,

There is no need to lock the balance shafts. The vibrations you describe do not sound like a typical balance shaft related issue. Whithout the balance shafts you will normally, if at all, feel the vibrations at idle and the less and less the higher you rev the engine.

If you want, you are welcome to send us an email and we will try and help you finding the cause.

/Hannes

Hi. I just bought the freewheel for balance shaft delete operation. Will be mounted on the car soon, when a new balance shaft assembly will arrive. My question is: – Is there a life span for the bearing on the sprocket? Do you recommend checking it at some intervals? And if yes can you change only the bearing or should be replaced as a whole. Thanks!

Hi,

if you bought our freewheel, then no. No need checking it after installation.

/Hannes

Hi, the freewheel fits in a golf MK6R 2.0 TFSI with engine code CDLF?

Yes, it does.

/Hannes

Hi, your articles have been very helpful diagnosing a recent failure I have just had, intermittent oil pressure warning light followed by complete Seized balance shaft, have managed to purchase a 2nd hand balance shaft assembly same part number as the one I removed from my BWA engine, but its from a Audi TT engine are the oil pumps the same pressure?

Hi Scott,

Yes they are.

BR

Hannes

I have a 2011 vw Tiguan 2.0 turbo 4 motion. I’m not sure if it’s the right one. Here is my vin number. Can you tell me if this will work? WVGBV7AX5BW519751. The oil pressure light goes on and off. I have an extended warranty that won’t pay for the repair. I’m at a loss. I need my car for work and can’t get a new one. The vw repair shop wants 2200$ to fix it.

Help

Hi John,

Unfortunately it looks like your engine is a EA888. This article refers to the EA113, which is a completely different design.

BR

Hannes

I thought I would not be so lucky

Any suggestions!?

Otherwise I’m gonna have to sell it for take a loss. The light comes on intermittently and sometimes not at all. The engine runs fine no noises. I had the oil sensor replaced in September and they put thicker oil in it. I like the car it only has 126,000 miles

I would start by reading the oil pressure with a manual gauge to see how it behaves.

BR

Hannes

why its not possible to undo the change ? i mean, if its just the wheel that must be changed to a “free wheel”…. you can put in the original wheel back again ..with matching timings of course … or not ?

Yes, our solution is reversible, whereas the poor man delete is not.

BR

Hannes

Hello, I have question about installation of freewheel, should I use also threadlocker – blue medium force, or just tighten the wheel bolt to balance shaft, with force of 50Nm only ?

Hi Greg,

if it is our freewheel, then there is no need for threadlocker.

/Hannes